Tuesday, February 15, 2011

Wednesday, May 12, 2010

Wednesday, February 10, 2010

Saturday, January 23, 2010

Tuesday, March 10, 2009

SAP Network Blog: First steps to work with Change Request Management scenario

Thursday, September 04, 2008

Wednesday, September 03, 2008

Thursday, August 28, 2008

Tuesday, May 15, 2007

In today’s businesses, Supply chains have evolved into complex Supply Networks and Collaboration between Supplier and Manufacturer is increasingly critical in reducing the Costs while maintaining visibility and assures better customer services. Getting an edge over the competition in any of these areas could potentially lead to better market share and profitability

Inventory Collaboration Hub which is now a part of the SCM suite is internet based and helps in sharing information between partners seamlessly and securely. The real benefits of ICH are :-

Real time synchronization of information – Changing demands and inventory levels

Ability to integrate with any Supplier IT infrastructure due to the interfacing technology

Use of various web based communication services to deliver proactive alerts

Ability to Track and audit transactions online helps in quality assurance

ICH can cut costs through reduction in inventory and safety Stock, reduction in overtimes, reduction in administrative costs due to lesser processing effort and reduction in expediting costs. There are lesser risks of Stock outs, production delays and increased accuracy in delivery dates thus increasing Customer Service Levels

Its quite a useful tool if you would like to use your existing planning and execution processes and tools to collaborate with the suppliers. SAP ICH enables you to standardize on your existing SAP solutions, has shorter implementation time and user-friendly functions

also check SAP help on ICH

and SNC in service market place

Aggregated Planning in SNP

Purpose

Planning large supply chain models is very performance intensive. To reduce the model complexity it should be possible to plan at an aggregated (less detailed) level.

Aggregated Planning in SNP allows customers to plan groups of products, like brands or regions, as opposed to planning for each individual product at each individual plant or warehouse. The SNP planning algorithms (heuristic, optimizer, capacity leveling) can be performed on product or location group level.

After the aggregated planning run the new replenishment elements on group level have to be disaggregated to item level by using a fair share rule (or any other mechanism) to ensure that plans are consistent at all levels of aggregation.

(A lot of the following scenario is based on a mix of SCM 4 and SCM 5)

Main advantages:

- Improve mid-to-long range inventory & capacity planning

- Performance improvements

- Planning process simplification, Reduced workload for the planner(s)

- Possibility to define additional constrains at group level

- Increase scope of planning models

Master Data

All masterdata necessary for running the heuristics or optimizer needs to be done. This is not covered in this section. It might help to read the section on Creating Hierarchies to get a clearer understanding

Create Products and Locations - The products and locations in the detailed level need to be created but along with that Products and Locations which are at the aggregated level could be Real (for eg hubs) or Virtual Products but need to be created. The settings of the aggregate planning objects need to be syncronised with the Member planning objects and also take into consideration the planning scenario.

The Location-Product hierarchies are generated based on the Location and the Product hierarchies (click on image for enlarged view).

The location product hierachies will have as nodes the Product Group in each location and in those nodes the Product - location combination.

Similarly Create Resources, PPMs/PDS and Transportation Lanes and corresponding PPM / PDS Hierarchy Resource HierarchyHow to create Hierarchies

Go to T Code= /SAPAPO/SCCRELHSHOW

Generating hierarchies: Enter SNP_LOC_HIER in hierarchy field. To add new Location object headers, right-click on SNP_LOC_HIER, and choose Attach object in hierarchy and in the selection window enter (Aggregate)Locations. To add new objects to the hierarchy, choose Continue

To attach Location object members to Aggregated location(object header), right-click on the Location object header, choose Attach object in hierarchy, and in the selection window enter (sub/member)Location number, then choose the check mark to continue

After adding all the objects, click on the hierarchy and then on the "Models" Button and select the relevant model (000) and save

Repeat similarly for Product (SNP_PROD_HIER) Hierarchy

To generate Location Product Hierarchies choose SNP_LOCPROD_HIER Hierarchy on the selection and choose "Display button" . Then choose the "Update" button. The Location Product Hierarchy will be generated automatically. Click on the hierarchy and choose the "Models" button and choose the relevant model and save

You can also create your own configuration for Hierarchies based on the Standard SAP provided ones.

You can also create your own configuration for Hierarchies based on the Standard SAP provided ones.

Aggregated Planning Area Configuration

Standard SNP Aggregated Planning book 9ASNPHRL or 9ASNPAGGR (depending on which version you are on) with data views SNPAGGR(1) and SNPAGGR(2) is based on the planning area 9ASNP02. You can create a copy of the Planning Area and the Planning Book/Data Views so that you can make your own modification to the structure.

This planning area contains the Key Figures needed for the aggregation planning book and has the relevant settings for it. Please note the settings for -

- Aggregation - The Aggregationindicator specifies whether the aggregated value or the normal value is calculated and displayed at header location product level in a key figure. This indicator also controls whether the value is kept or deleted at sub product level after aggregation Value 1 - Aggregate at group level, retain value at detailed level or 2- Aggregate at group level, Delete value at detailed level. SCM 5 also has 3 and 4. Non aggregation related KF have no entry in this field

- Key Figure Functions -KF functions define the business meaning of a key figure behaves. SNP uses this business meaning to decide how to use a key figure during planning. Aggregated Kf usually take the value 9001 to 9026.

- Also note the CatGr which will be aggregated and the Category to which any new orders created will be written to. You might have to make changes to the IMG if you want to change the order categories that the KF read.

- Make sure the Aggregated Planning tab of the planning area has the relevant heirarchy structures attached to them

- The Hierarchical planning book also contains auxiliary key figure NETDM that SNP disaggregation uses as a basis for determining product demand. The system uses macro Net Requirements (Disaggregation) to calculate the net requirements at sub product level that are stored in this key figure and takes into account the stock on hand. It ignores the demand from previous periods (shown in the Supply Shortage key figure) and only considers the demand starting with the period containing the value to be disaggregated.If you wish to calculate product demand differently for SNP disaggregation, you can also create your own demand key figure for the planning book as an auxiliary key figure and use a macro to define your calculation formula. Assign key figure function 9010 (Aggr. Planning: Disaggregation Demand) to this key figure.

Interactive Aggregated Planning Process

Selection of Data:

Go to Interactive Planning book /SAPAPO/SDP94

Load Planning Book/Data View 9ASNPHRPL / SNPHRPL (or 9ASNPAGGR in SCM5)

How you choose the selection id depends on what you want to see. for eg in the shuffler for selection id - choose

Show : APO Location product

APO Planning Version : 000 (or the one you want to use)

Product: use a APO Location product (Header) and Location: use a (Member) Location

This will bring up all the Headers at the member location.

You could also choose

Show : APO Location product (Header)

APO Planning Version : 000 (or the one you want to use)

Product: use a APO Location product (member) and Location: use a (Member) Location

Loading Data

You can now see the forecast (assuming you have released it ) of the members and also the aggregated forecast

Similarly all other Demand and Reciept and Stock Kfs would be populated. Ensure you have the right figures at the Aggregated level. Also make sure the view helps the user to understand the aggregation process. the forecast seen at the aggregated level is not where the forecast actually resides.

Execute SNP planing. Heuristics or Optimizers can be used. This can also be planned in the background. Depending on the Masterdata setting you would be creating Planned orders for production or procurement. You can notice this happens at the aggregated level while actually there is no forecast at the aggregated level.

Once this is done, Capacity Planning and SNP disaggregation can be done. But i will leave it for another post

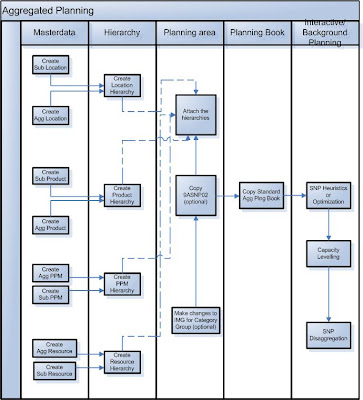

Pl see the flow diagram for the Setup and working of Aggregated planning.

A lot of the details here are from SAP help. Please check the SAP HELP on AGGREGATED Planning for more details

Please comment for changes and questions.

(my thanks to Wolfgang Eddigehausen for helping me in this topic)

Monday, May 14, 2007

In today’s businesses, Supply chains have evolved into complex Supply Networks and Collaboration between Supplier and Manufacturer is increasingly critical in reducing the Costs while maintaining visibility and assures better customer services. Getting an edge over the competition in any of these areas could potentially lead to better market share and profitability

Inventory Collaboration Hub which is now a part of the SCM suite is internet based and helps in sharing information between partners seamlessly and securely. The real benefits of ICH are :-

Real time synchronization of information – Changing demands and inventory levels

Ability to integrate with any Supplier IT infrastructure due to the interfacing technology

Use of various web based communication services to deliver proactive alerts

Ability to Track and audit transactions online helps in quality assurance

ICH can cut costs through reduction in inventory and safety Stock, reduction in overtimes, reduction in administrative costs due to lesser processing effort and reduction in expediting costs. There are lesser risks of Stock outs, production delays and increased accuracy in delivery dates thus increasing Customer Service Levels

Its quite a useful tool if you would like to use your existing planning and execution processes and tools to collaborate with the suppliers. SAP ICH enables you to standardize on your existing SAP solutions, has shorter implementation time and user-friendly functions

also check SAP help on ICH

and SNC in service market place

Sunday, May 13, 2007

Aggregated Planning in SNP

Purpose

Planning large supply chain models is very performance intensive. To reduce the model complexity it should be possible to plan at an aggregated (less detailed) level.

Aggregated Planning in SNP allows customers to plan groups of products, like brands or regions, as opposed to planning for each individual product at each individual plant or warehouse. The SNP planning algorithms (heuristic, optimizer, capacity leveling) can be performed on product or location group level.

After the aggregated planning run the new replenishment elements on group level have to be disaggregated to item level by using a fair share rule (or any other mechanism) to ensure that plans are consistent at all levels of aggregation.

(A lot of the following scenario is based on a mix of SCM 4 and SCM 5)

Main advantages:

- Improve mid-to-long range inventory & capacity planning

- Performance improvements

- Planning process simplification, Reduced workload for the planner(s)

- Possibility to define additional constrains at group level

- Increase scope of planning models

Master Data

All masterdata necessary for running the heuristics or optimizer needs to be done. This is not covered in this section. It might help to read the section on Creating Hierarchies to get a clearer understanding

Create Products and Locations - The products and locations in the detailed level need to be created but along with that Products and Locations which are at the aggregated level could be Real (for eg hubs) or Virtual Products but need to be created. The settings of the aggregate planning objects need to be syncronised with the Member planning objects and also take into consideration the planning scenario.

The Location-Product hierarchies are generated based on the Location and the Product hierarchies (click on image for enlarged view).

The location product hierachies will have as nodes the Product Group in each location and in those nodes the Product - location combination.

Similarly Create Resources, PPMs/PDS and Transportation Lanes and corresponding PPM / PDS Hierarchy Resource HierarchyHow to create Hierarchies

Go to T Code= /SAPAPO/SCCRELHSHOW

Generating hierarchies: Enter SNP_LOC_HIER in hierarchy field. To add new Location object headers, right-click on SNP_LOC_HIER, and choose Attach object in hierarchy and in the selection window enter (Aggregate)Locations. To add new objects to the hierarchy, choose Continue

To attach Location object members to Aggregated location(object header), right-click on the Location object header, choose Attach object in hierarchy, and in the selection window enter (sub/member)Location number, then choose the check mark to continue

After adding all the objects, click on the hierarchy and then on the "Models" Button and select the relevant model (000) and save

Repeat similarly for Product (SNP_PROD_HIER) Hierarchy

To generate Location Product Hierarchies choose SNP_LOCPROD_HIER Hierarchy on the selection and choose "Display button" . Then choose the "Update" button. The Location Product Hierarchy will be generated automatically. Click on the hierarchy and choose the "Models" button and choose the relevant model and save

You can also create your own configuration for Hierarchies based on the Standard SAP provided ones.

You can also create your own configuration for Hierarchies based on the Standard SAP provided ones.

Aggregated Planning Area Configuration

Standard SNP Aggregated Planning book 9ASNPHRL or 9ASNPAGGR (depending on which version you are on) with data views SNPAGGR(1) and SNPAGGR(2) is based on the planning area 9ASNP02. You can create a copy of the Planning Area and the Planning Book/Data Views so that you can make your own modification to the structure.

This planning area contains the Key Figures needed for the aggregation planning book and has the relevant settings for it. Please note the settings for -

- Aggregation - The Aggregationindicator specifies whether the aggregated value or the normal value is calculated and displayed at header location product level in a key figure. This indicator also controls whether the value is kept or deleted at sub product level after aggregation Value 1 - Aggregate at group level, retain value at detailed level or 2- Aggregate at group level, Delete value at detailed level. SCM 5 also has 3 and 4. Non aggregation related KF have no entry in this field

- Key Figure Functions -KF functions define the business meaning of a key figure behaves. SNP uses this business meaning to decide how to use a key figure during planning. Aggregated Kf usually take the value 9001 to 9026.

- Also note the CatGr which will be aggregated and the Category to which any new orders created will be written to. You might have to make changes to the IMG if you want to change the order categories that the KF read.

- Make sure the Aggregated Planning tab of the planning area has the relevant heirarchy structures attached to them

- The Hierarchical planning book also contains auxiliary key figure NETDM that SNP disaggregation uses as a basis for determining product demand. The system uses macro Net Requirements (Disaggregation) to calculate the net requirements at sub product level that are stored in this key figure and takes into account the stock on hand. It ignores the demand from previous periods (shown in the Supply Shortage key figure) and only considers the demand starting with the period containing the value to be disaggregated.If you wish to calculate product demand differently for SNP disaggregation, you can also create your own demand key figure for the planning book as an auxiliary key figure and use a macro to define your calculation formula. Assign key figure function 9010 (Aggr. Planning: Disaggregation Demand) to this key figure.

Interactive Aggregated Planning Process

Selection of Data:

Go to Interactive Planning book /SAPAPO/SDP94

Load Planning Book/Data View 9ASNPHRPL / SNPHRPL (or 9ASNPAGGR in SCM5)

How you choose the selection id depends on what you want to see. for eg in the shuffler for selection id - choose

Show : APO Location product

APO Planning Version : 000 (or the one you want to use)

Product: use a APO Location product (Header) and Location: use a (Member) Location

This will bring up all the Headers at the member location.

You could also choose

Show : APO Location product (Header)

APO Planning Version : 000 (or the one you want to use)

Product: use a APO Location product (member) and Location: use a (Member) Location

Loading Data

You can now see the forecast (assuming you have released it ) of the members and also the aggregated forecast

Similarly all other Demand and Reciept and Stock Kfs would be populated. Ensure you have the right figures at the Aggregated level. Also make sure the view helps the user to understand the aggregation process. the forecast seen at the aggregated level is not where the forecast actually resides.

Execute SNP planing. Heuristics or Optimizers can be used. This can also be planned in the background. Depending on the Masterdata setting you would be creating Planned orders for production or procurement. You can notice this happens at the aggregated level while actually there is no forecast at the aggregated level.

Once this is done, Capacity Planning and SNP disaggregation can be done. But i will leave it for another post

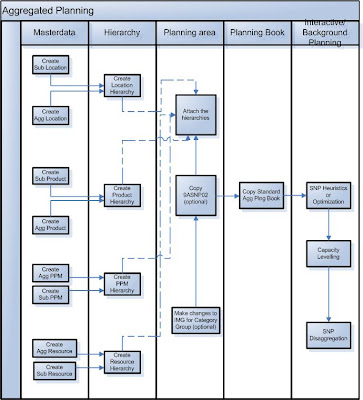

Pl see the flow diagram for the Setup and working of Aggregated planning.

A lot of the details here are from SAP help. Please check the SAP HELP on AGGREGATED Planning for more details

Please comment for changes and questions.

Tuesday, October 22, 2002

Manugistics used its recent user conference to unveil a totally updated architectural framework — Manugistics 7 — and to promote its Enterprise Profit Optimization (EPO) Vision.

Manugistics 7 is a Java-deployable Internet solution that does not rely on Microsoft technology, thereby easing any customers' concerns of hardware and operating system deployability. Removing the dependence on client-server technology also takes away the related application maintenance burden. Moreover, the browser-based solution means that it can be deployed as needed for employees and trading partners.

Manugistics 7 EPO is a componentized solution suite made up of modular applications that broadly incorporate Supply Chain Management (SCM), Customer Relationship Management (CRM), and Pricing and Revenue Optimization (PRO). Customers can pick and choose only the "pieces" that are most desperately needed to address current business challenges and later add additional solutions as the business needs dictate.

Wednesday, October 16, 2002

Forecasts will never quite match actual data; rather than ignore forecasts completely, measure and then manage the forecast to improve the forecasting process.

Statistical knowledge is needed to measure the forecasting process.

Forecast measures should be meaningful, actionable, and robust.

Reward (pay) forecasters and their managers based on forecast accuracy.

Monday, October 14, 2002

Manugistics used its recent user conference to unveil a totally updated architectural framework — Manugistics 7 — and to promote its Enterprise Profit Optimization (EPO) Vision.

Manugistics 7 is a Java-deployable Internet solution that does not rely on Microsoft technology, thereby easing any customers' concerns of hardware and operating system deployability. Removing the dependence on client-server technology also takes away the related application maintenance burden. Moreover, the browser-based solution means that it can be deployed as needed for employees and trading partners.

Manugistics 7 EPO is a componentized solution suite made up of modular applications that broadly incorporate Supply Chain Management (SCM), Customer Relationship Management (CRM), and Pricing and Revenue Optimization (PRO). Customers can pick and choose only the "pieces" that are most desperately needed to address current business challenges and later add additional solutions as the business needs dictate.

Tuesday, September 17, 2002

In APO Demand Planning, you can plan promotions or other special events separately from the rest of your forecast. You can use Promotion Planning to record either one-time events, such as an earthquake, or repeated events such as quarterly advertising campaigns. Other examples of promotions are trade fairs, coupons, free-standing inserts, competitors' activities, market intelligence. Examples of events that also have an impact on consumer behavior are upward/downward economic trends, and acts of nature, such as tornadoes etc.

The advantages of planning promotions separately are:

You can compare forecasts with promotions to those without promotions.

You can correct the sales history by extracting past promotions from it, thus obtaining unpromoted historical data for the baseline forecast.

The processes of interactive planning and promotion planning can be kept completely separate. For example, the sales force might be responsible for interactive planning while marketing is responsible for promotion planning.

Promotional uplifts can be defined in units or percentages by promotion patterns. A promotion pattern that occurred in the past can be automatically detected and recreated for future periods. A promotion pattern can be archived in a promotion catalog; it can therefore be reused if a promotion of the same type is repeated.